FLUE GAS FLOW MEASUREMENT

FLUE GAS FLOW MEASUREMENT

Control & Instrumentation

Continuous Emission Monitoring Solutions

Flue Gas Flow Measurement for Power Plants

With growing environmental regulations, power plants face increasing demands to monitor and control emissions more precisely. Accurate flue gas measurement is crucial—not only for maintaining compliance, but also for improving combustion efficiency and reducing operational costs.

The Challenge: Unstable Flow Conditions

Accurate flue gas monitoring is no simple task.

Fluctuating load demands and variable fuel quality often lead to unstable flow within stacks and ducts. These ever-changing conditions make it difficult for conventional flow meters to deliver consistent, reliable data. To complicate matters further, the design of large stack systems typically results in non-uniform and turbulent flow profiles, which standard flow technologies struggle to measure accurately.

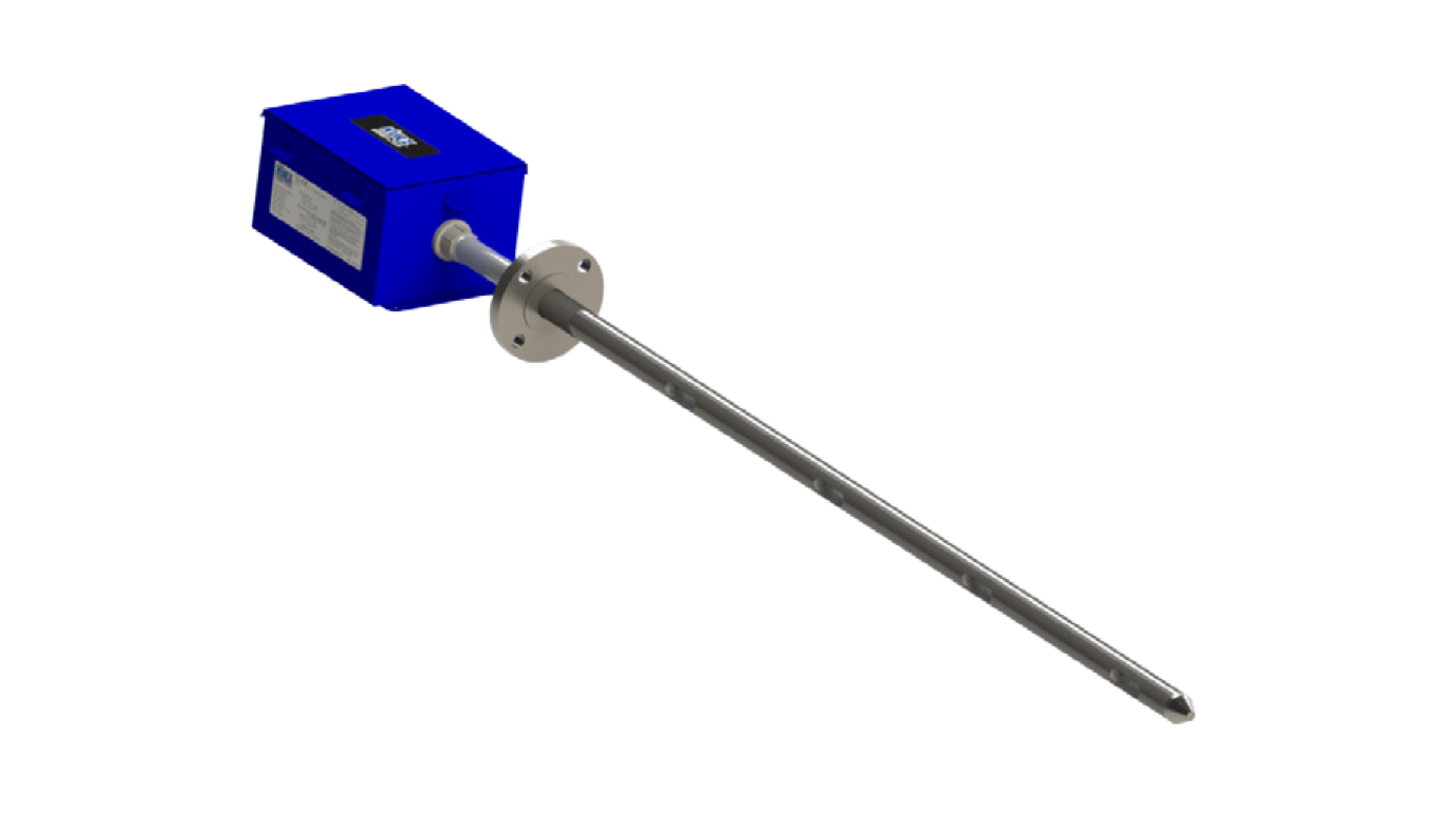

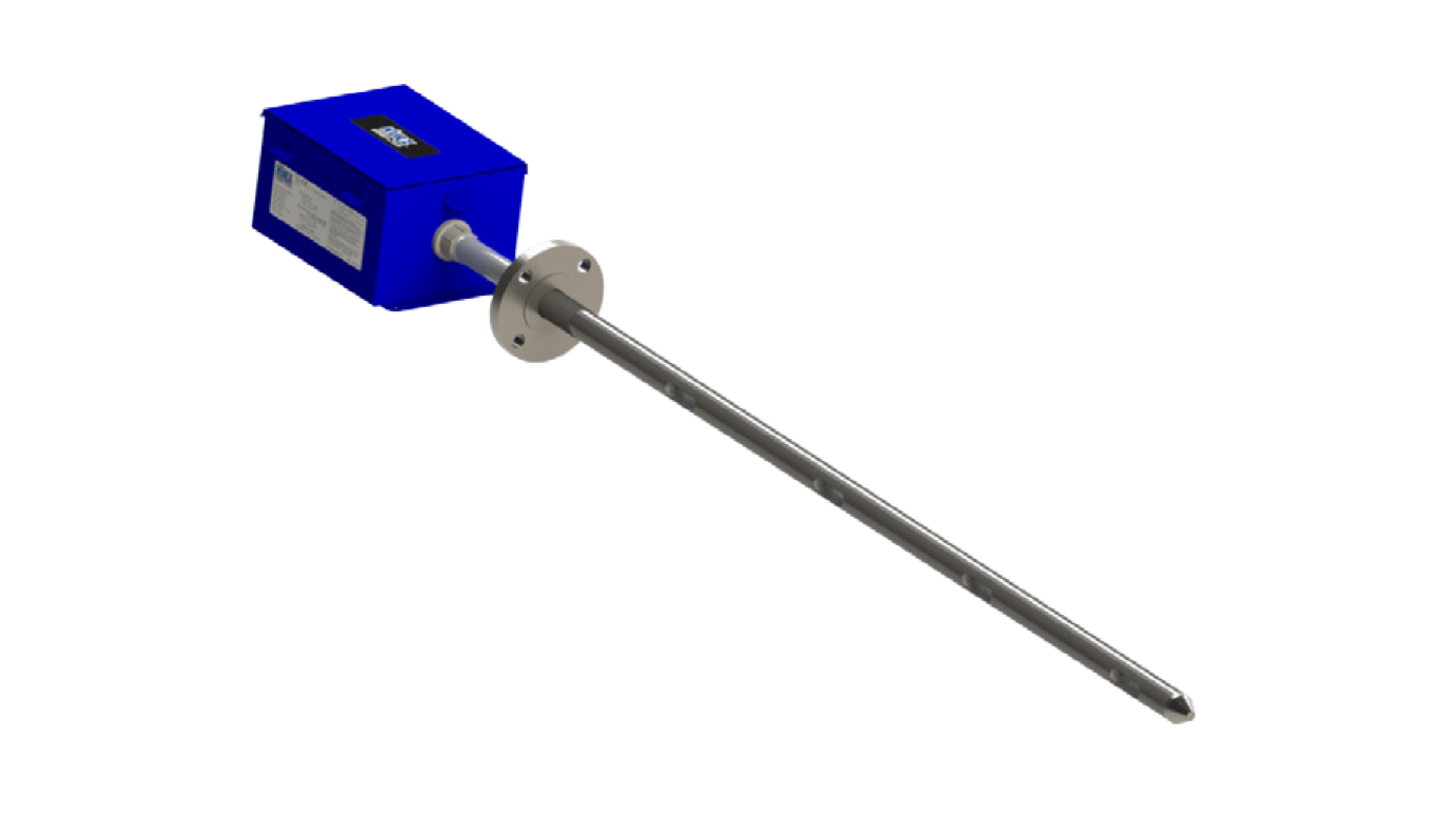

Our Solution: MULTIPOINT INSERTION MASS FLOWMETER – K-BAR

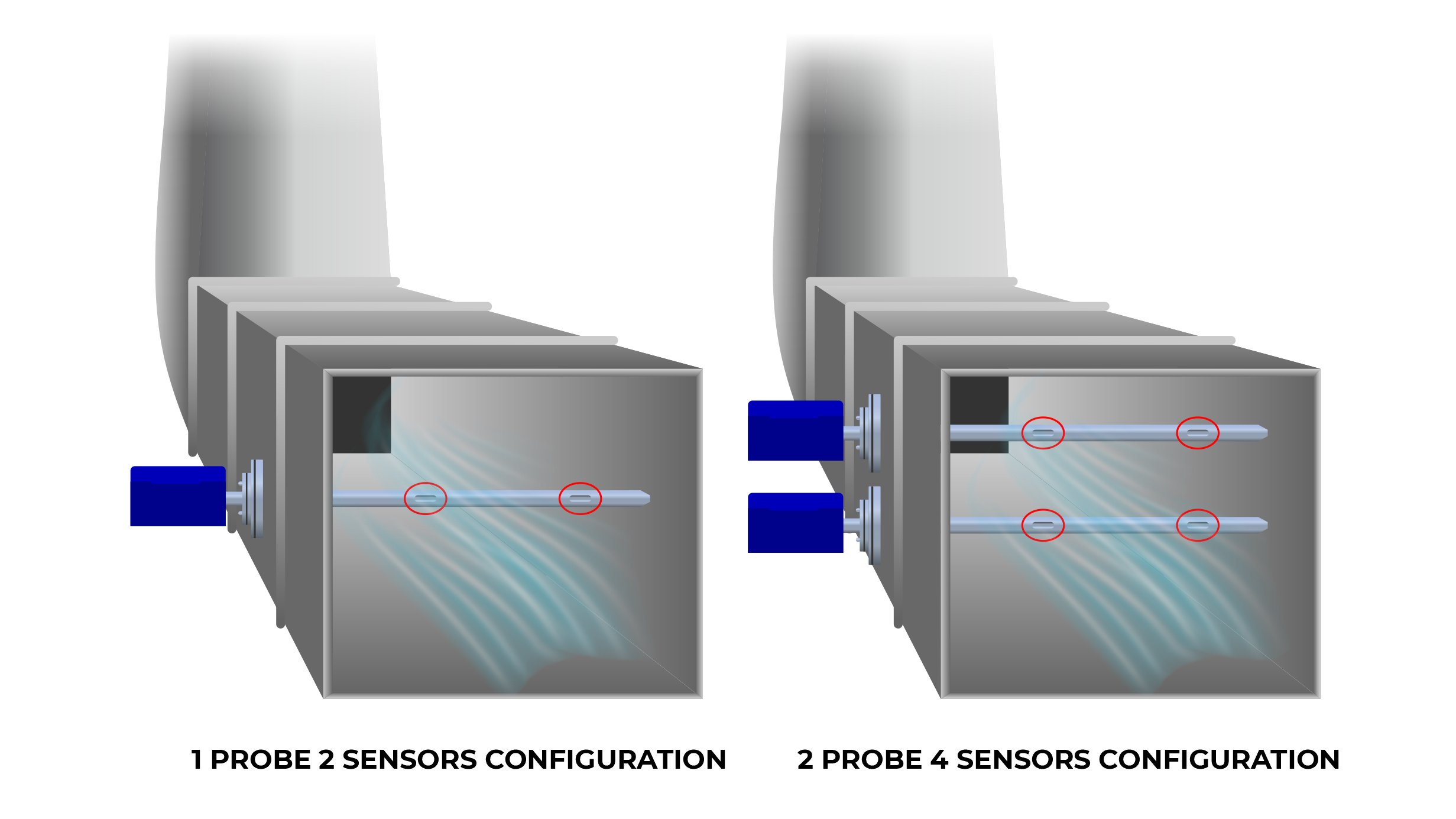

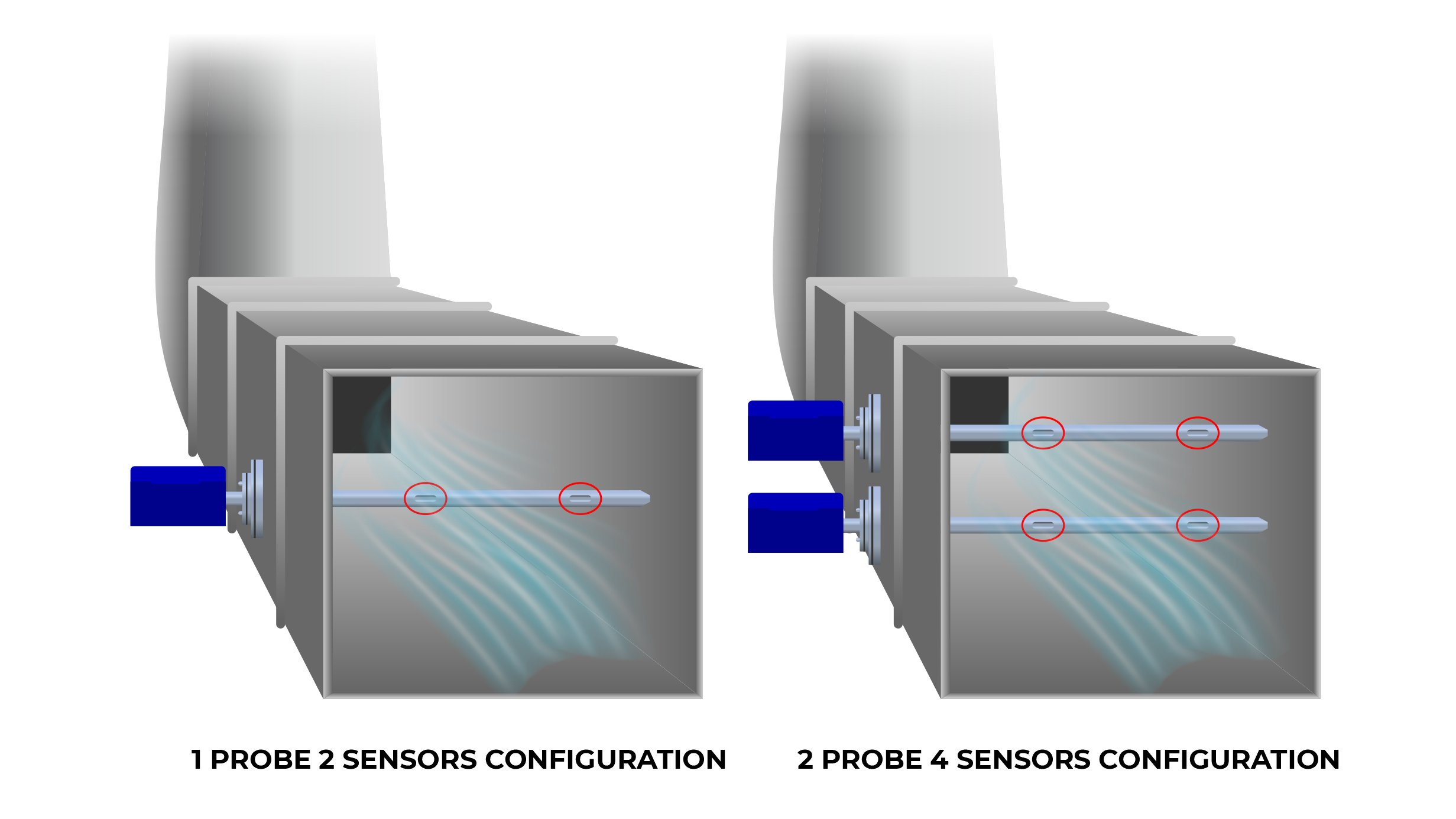

Designed to perform in tough and dusty environment, conditions, our K-BAR Multipoint Insertion Mass Flowmeter provides continuous, real-time, and highly accurate mass flow measurements in large ducts and stacks. Its multipoint sensing design ensures reliable data even under complex conditions such as irregular velocity profiles, dirty gas streams, wide temperature variations, high turn-down ratios, and rapid shifts in flow dynamics.

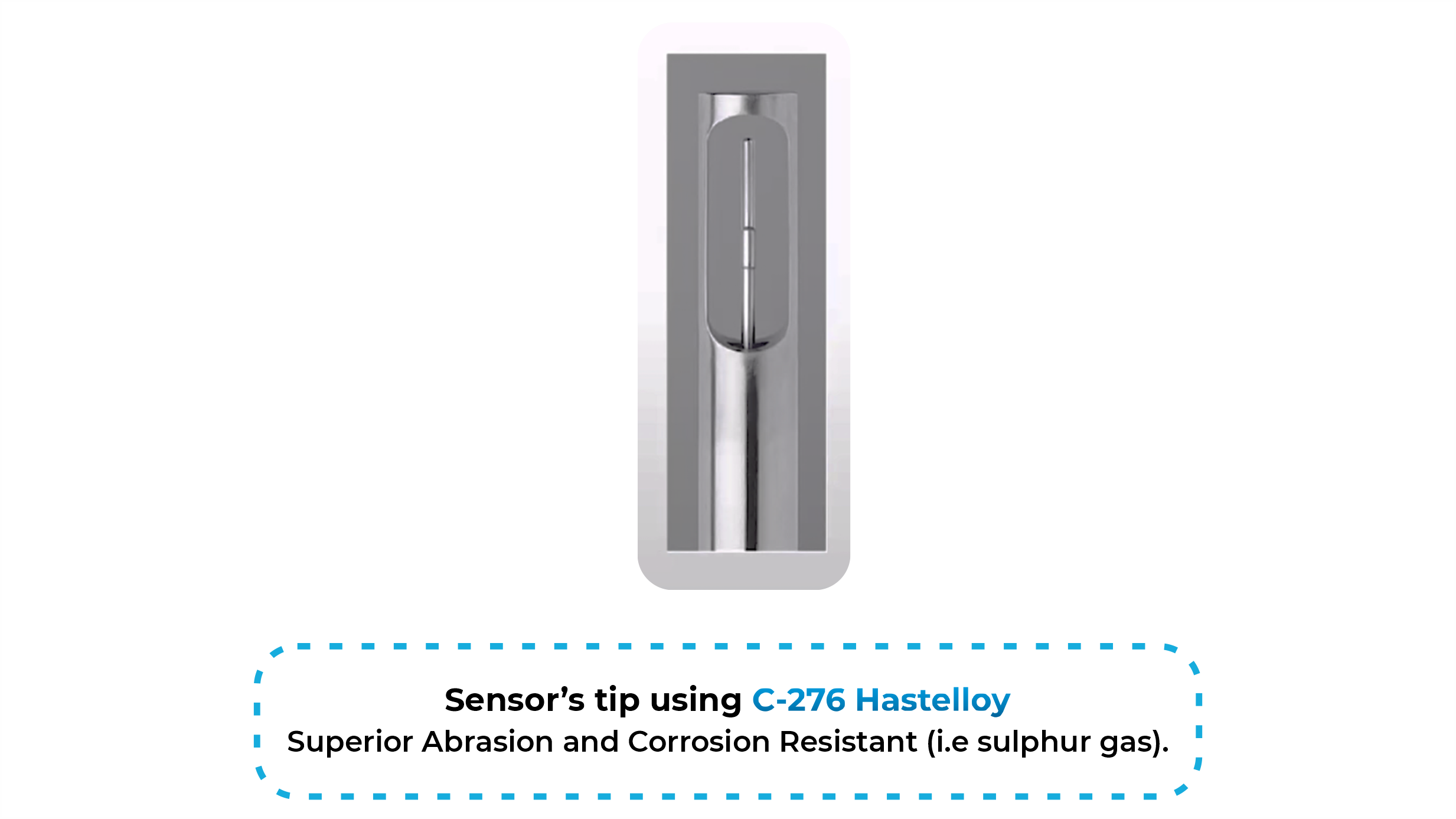

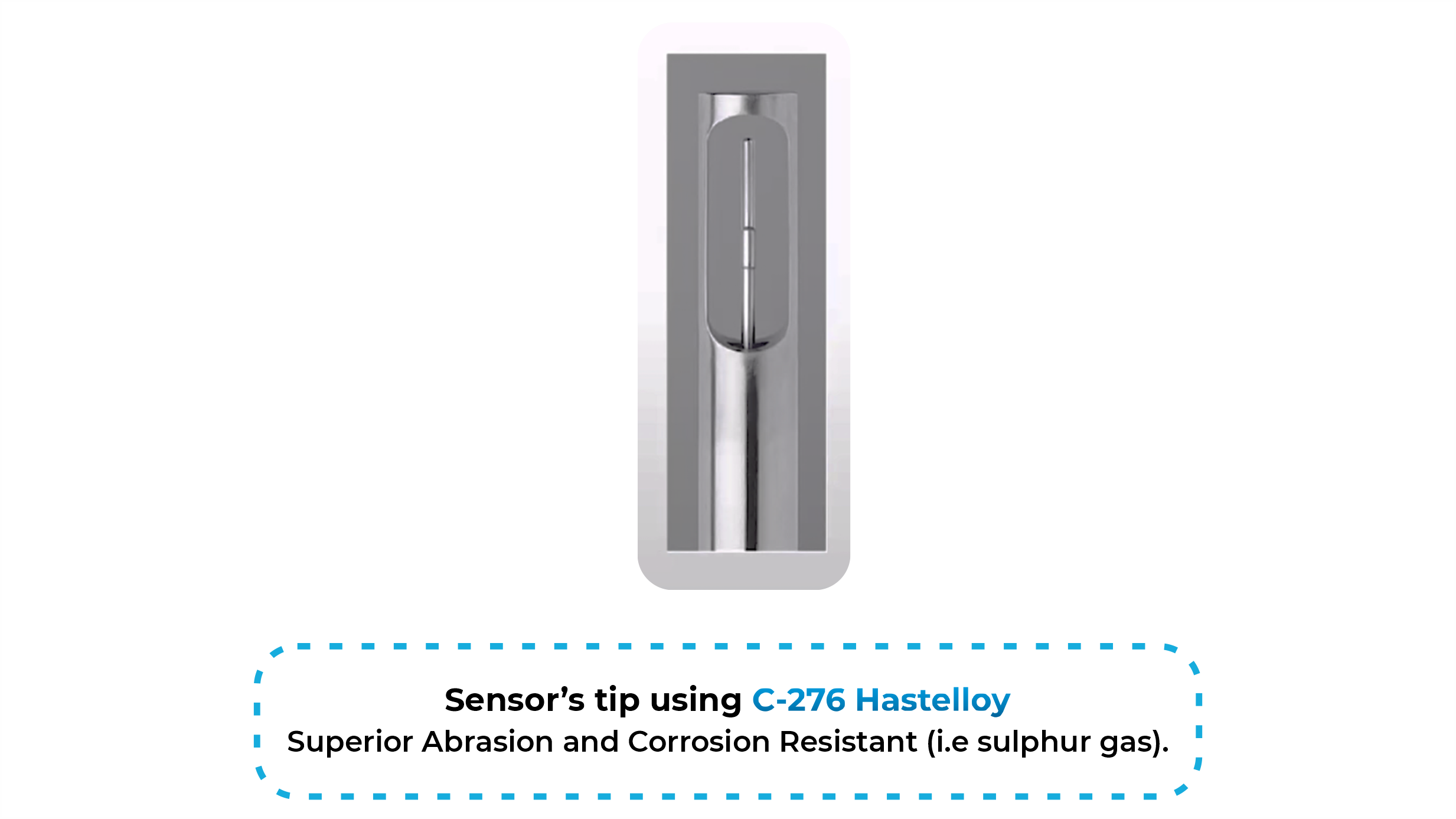

Engineered for long-term durability, K- Bar is built with corrosion-resistant Hastelloy® C-276 sensor tips to withstand high-sulfur, dusty environments without the clogging issues which often seen in traditional Pitot tube systems. Most importantly, it is Emission compliance-ready, meeting both US EPA CHG certification (40 CFR 98.34) and EU AMS (EN14181 QAL1) requirements—making it a trusted solution for emission monitoring across power plants.

Why Choose Our Solution

The constant-temperature thermal mass flow technology offers a high signal-to-flow ratio, dependable accuracy, excellent repeatability, and requires minimal maintenance—making it a reliable, cost-effective choice for continuous emission monitoring in demanding environments.