HYDRO GENERATOR CONDITION MONITORING

Control & Instrumentation

Protect the critical asset has never become easier than before.

- Simplicity – Only one hardware module

- Intelligent – Automatic Fault Diagnostic of the hydro turbine generator.

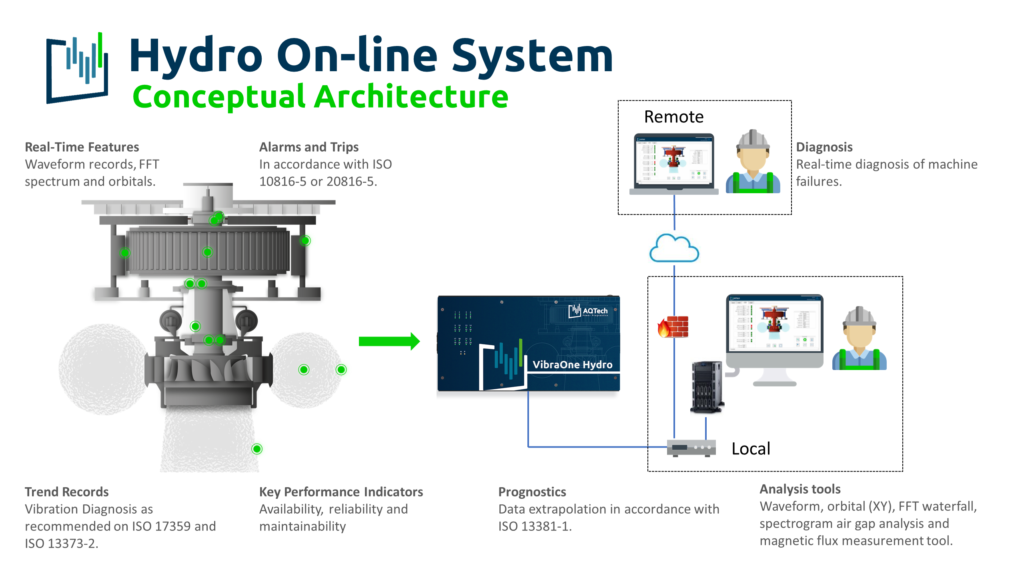

The solution provides continuous monitoring and recording of the conditions of hydroelectric turbines and generators, detecting faults and disturbances, enabling constant validation of the operation and design of field systems.

Real time features:

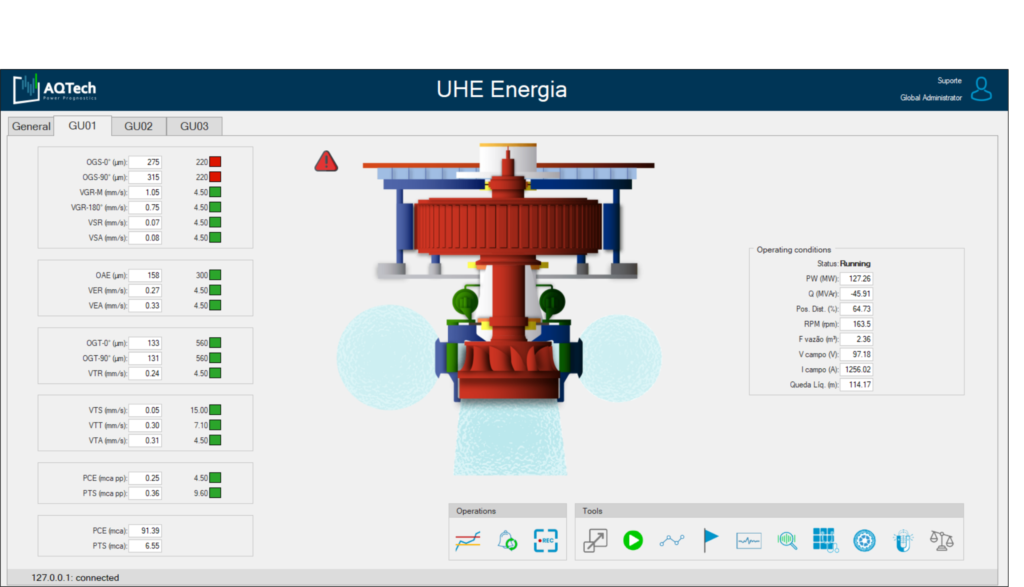

- High-performance hardware and software that allows real-time visualization of vibration data.

- With a supervision screen, you can monitor global values, vibration level alarms (ISO 20816), and operating data, received through industrial protocols via the Local SCADA integration.

Analysis Tools

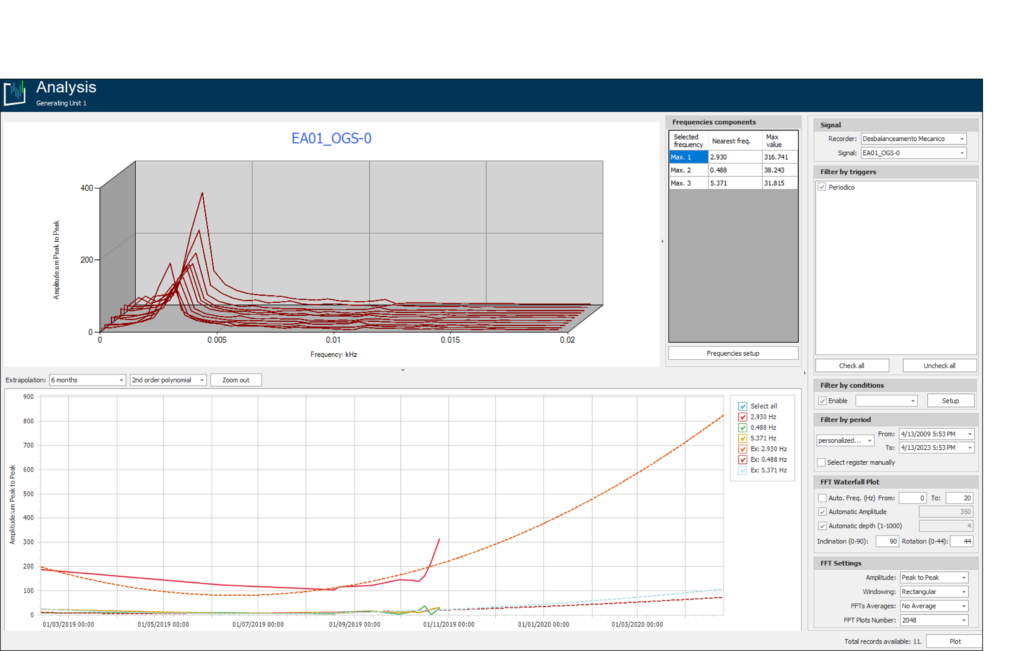

- Our post-processing software offers advanced vibration analysis tools, including waveform, orbital (XY), FFT cascade, and spectrogram analysis according to 150 13373-2 standards.

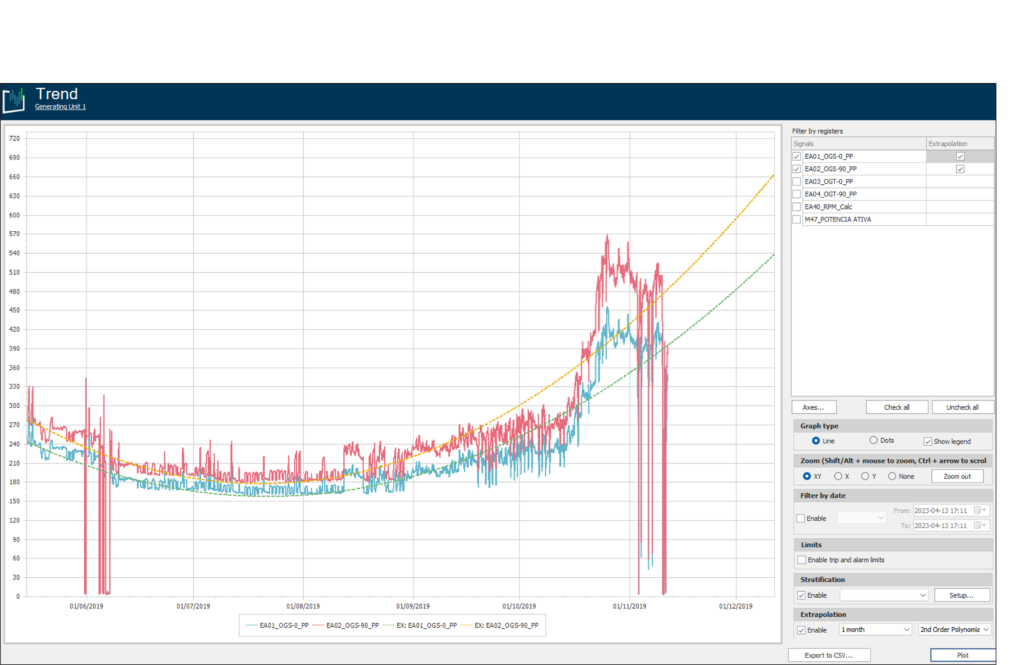

Trend and Diagnosis

- In the context of predictive maintenance, estimating remaining machine life (RUL) and end-of-life (EOL) is crucial. AQTech software uses the ISO 13381-1 standard to extrapolate global vibration data and values associated with frequency spectrum ranges that are closely linked to fault diagnosis.

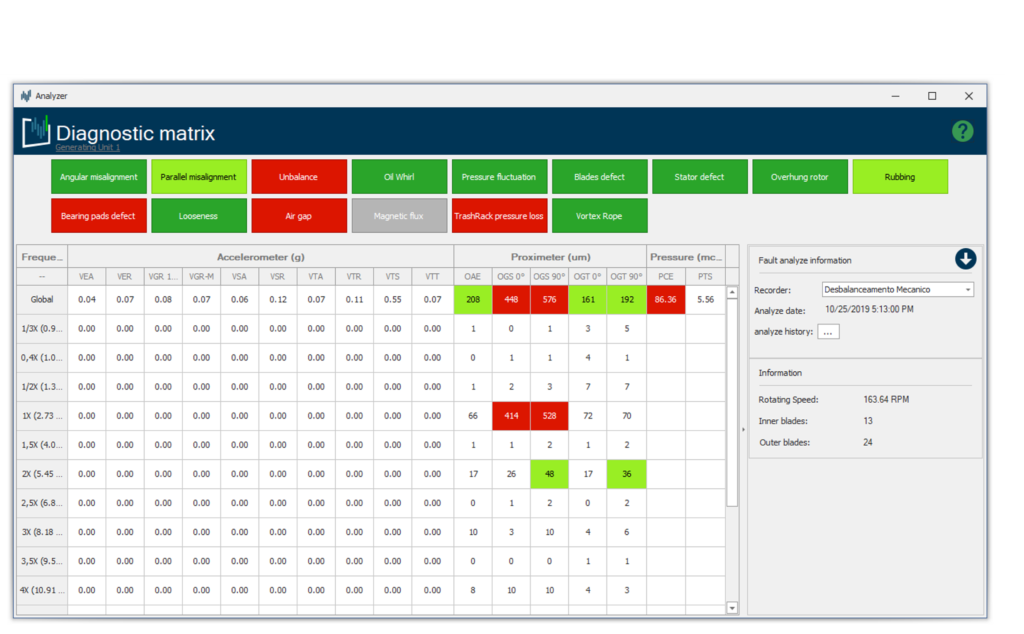

Automatic machine fault diagnosis

- Automatic machine fault diagnosis is performed by detecting specific harmonic frequencies associated with the nominal rotation of the generating unit.

- The Analyzer is equipped with pre-registered failure modes, including unbalance (mechanical, magnetic, hydraulic), misalignment (angular, parallel), failures in the generator stator, turbine failures (rotor blades, guide vanes), problems in the hydraulic flow, pressure actuation, clearance, oil whirl, and bearing shoe failures, in accordance with ISO 13373-1, ISO 13373-3, and ISO 13373-7.

- Furthermore, it is customized for each plant accordingly.

Automatic Diagnostic

Automatic machine fault diagnosis is perfomed by detecting specific harmonic frequencies associated with the nominal rotation of the generating unit. The Analyzer is equipped with pre-registered failure modes, including unbalance (mechanical, magnetic, hydraulic), misalignment (angular, parallel), failures in the generator stator, turbine failures (rotor blades, guide vanes), problems in the hydraulic flow, pressure actuation, clearance, oil whirl, and bearing shoe failures, in accordance with ISO 13373-1, ISO 13373-3, and ISO 13373-7. The diagnostic tool also allows users to create new failure modes through logical blocks, mathematical operations, constant inputs, output blocks, text boxes, Boolean operation blocks, and notifications resulting algorithms.

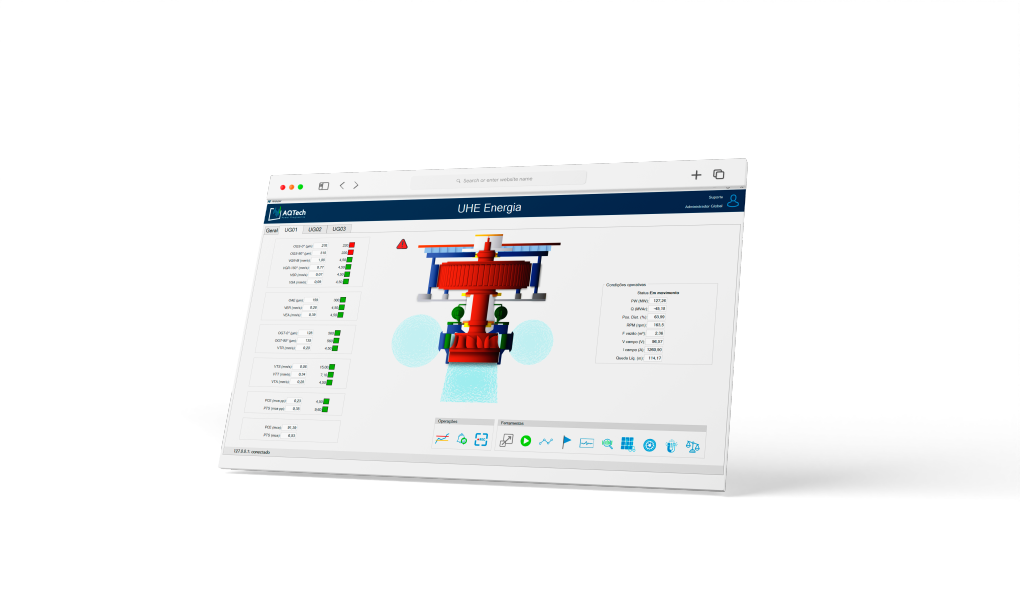

Analysis Tools

Our post-processing software offers advanced vibration analysis tools, including waveform, orbital (XY), FFT cascade, and spectrogram analysis according to ISO 13373-2 standards. With additional mathematical and statistical operations, our software enables specialized engineering professionals to conduct in-depth evaluations. Long-term trend records and analysis tools support vibration diagnosis, as recommenden in ISO 17359 and ISO 13373-2 standards. Additionally, the software includes an air gap analysis tool, which helps prevent failures such as rubbing between the rotor and stator, and a magnetic flux measurement tool.

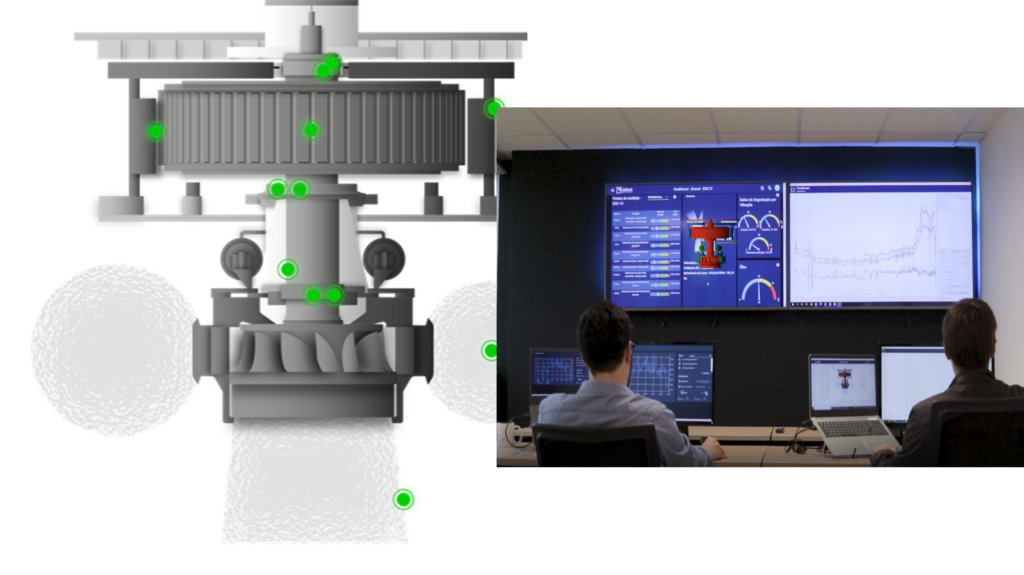

Real-time Features

High-performance hardware and software that allows real-time visualization of vibration data. With a supervision screen, you can monitor global values, vibration level alarms (ISO 20816), and operating data, received through industrial protocols via the local SCADA integration. Additionally, our real-time visualization tool provides waveforms, FFT spectri, and orbitals, making it ideal for field testing, such as machine commissioning, operating range tests, index tests, and more. You can also configure the signal acquisition rate, monitor multiple variables in real-time, and generate records for later analysis in specific operating conditions of the generating unit.

Trend and Diagnosis

In the context of predictive maintenance, estimating remaining machine life (RUL) and end-of-life (EOL) is crucial. AQTech software uses the ISO 13381-1 standard to extrapolate global vibration data and values associated with frequency spectrum ranges that are closely linked to fault diagnosis. AQTech has extensive expertise in applying predictive models based on statistical and machine learning (ML) techniques, including Auto-Regressive (AR) models such as ARIMA (Autoregressive Integrated Moving Average).

AQTECH BENEFITS :

- Know-how in monitoring generators and turbines

- Own solution (own development of hardware and software – technological domain)

- Possibility of integrating the system with sensors from different manufacturers

- Possibility of exporting raw data (.csv files)

- Intuitive software in English and without additional licenses

- Self-Diagnostic Tool for failure modes

- Excellent technical support