INLINE COAL SIZER

INLINE COAL SIZER

Optimization

Optimize Power Plant Operation & Performance

Power plants are accelerating their digital transformation journey to boost operational efficiency, improve maintenance, and enable smarter, data-driven decision making. At the same time, Indonesia’s ambitious biomass co-firing program aims to reduce coal emissions by demanding 4-9 million tonnes of biomass annually.

This transition brings new challenges. Blending various coal grades and biomass changes fuel characteristics, making combustion more complex. Therefore, controlling coal particle fineness has become more critical than ever.

Why Coal Fineness Matters in Pulverized Coal (PC) Boilers

In the PC Boiler, coal is ground finely and distributed to the burner in suspension, followed by the combustion occurs similarly to natural gas firing.

Optimizing pulverized fuel milling is essential for efficient furnace combustion and emission reduction, which depends heavily on achieving the optimum coal particle size.

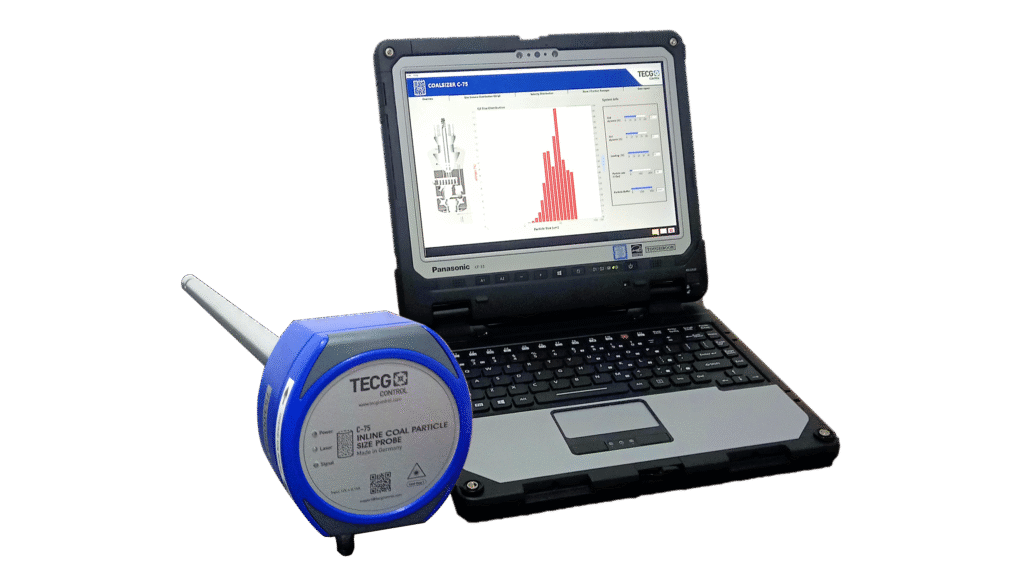

INLINE PULVERISED COAL SIZE MEASUREMENT

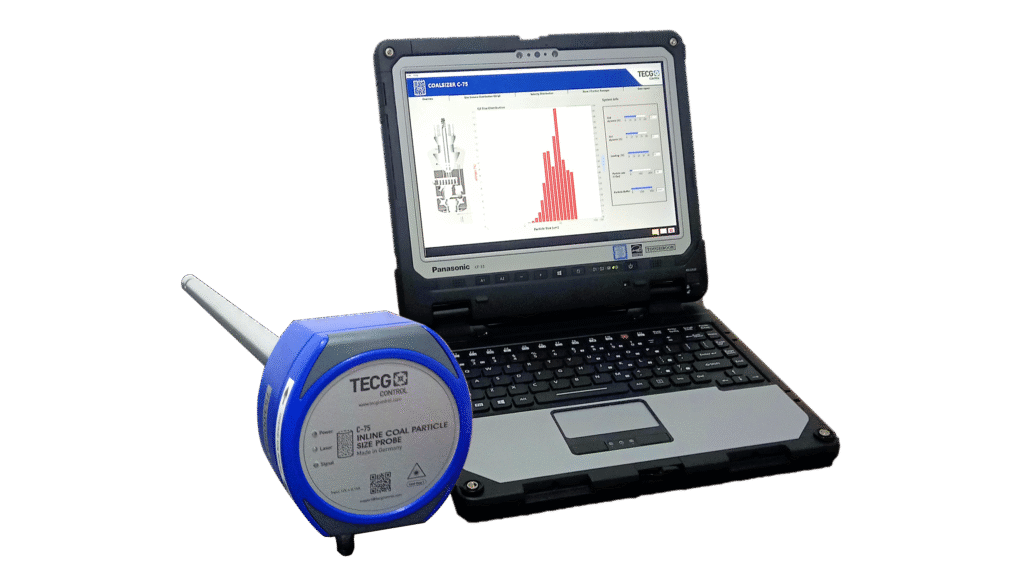

C-75 Coal Sizer Particle Probe provides real-time insight into coal size distribution directly in the coal pipe:

- Installed inline within the coal pipe and delivering instant results.

- Utilizes patented laser-based technology to sample and measure thousands of particles online, ensuring highly reliable and accurate output.

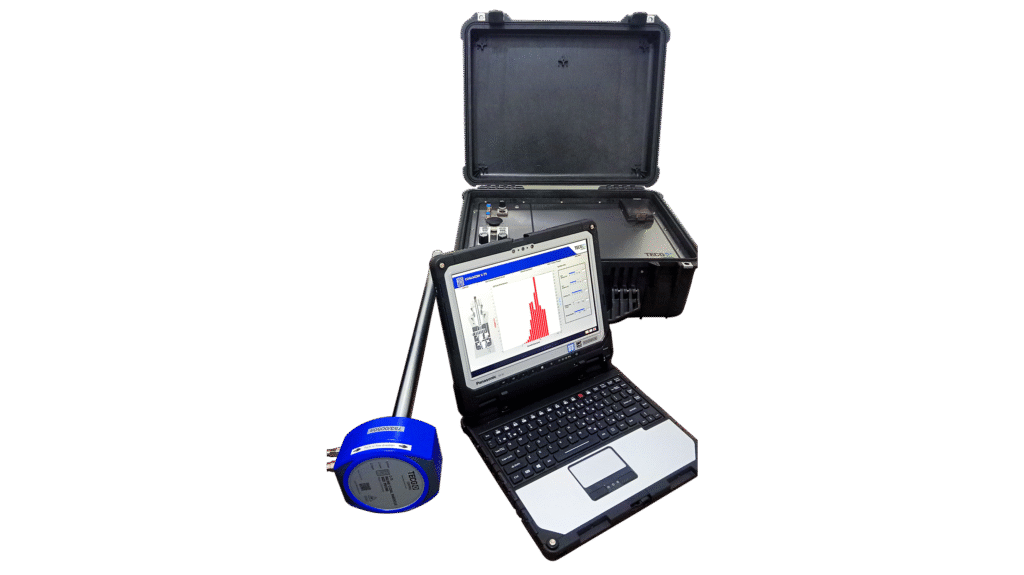

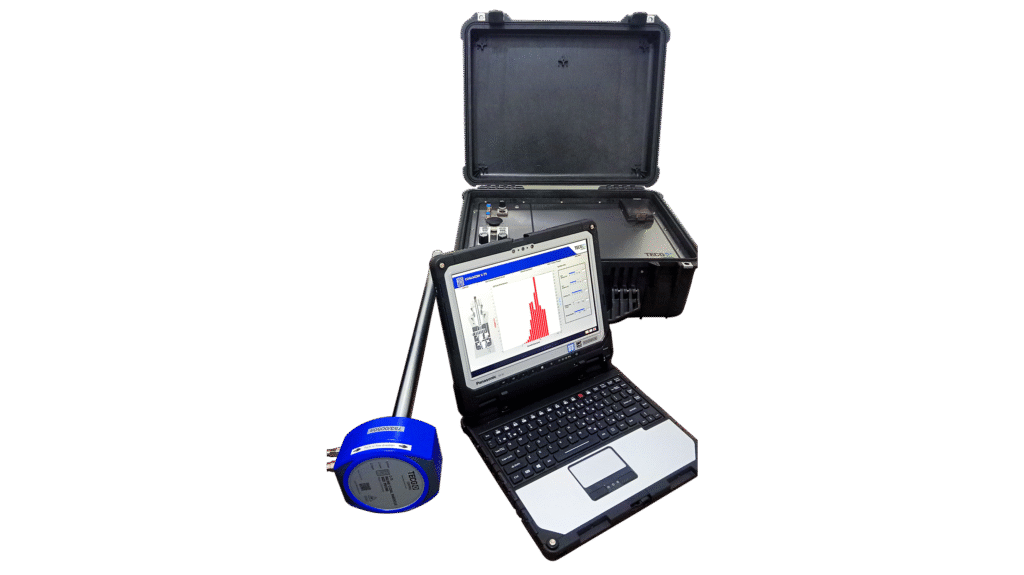

Portable Coal Size Measurement – Key Features

Supreme Measurement Capability:

- Real-time, comprehensive measurement.

- Easy & flexible installation:

- Direct insertion into coal pipes

- Portable options available

- Minimal Installation effort with no need for alignment or field calibration

Optimizing the Pulverizer Output

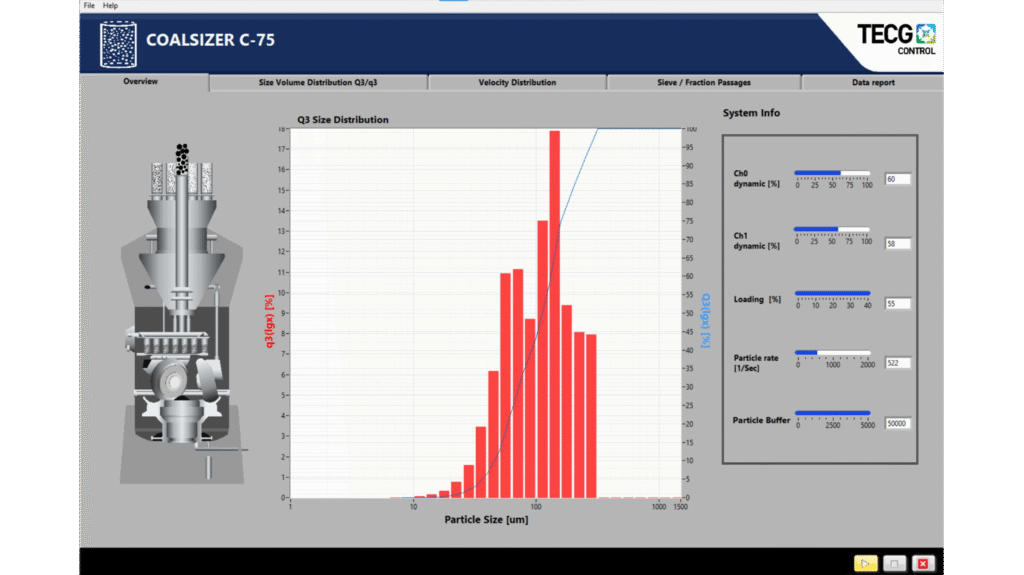

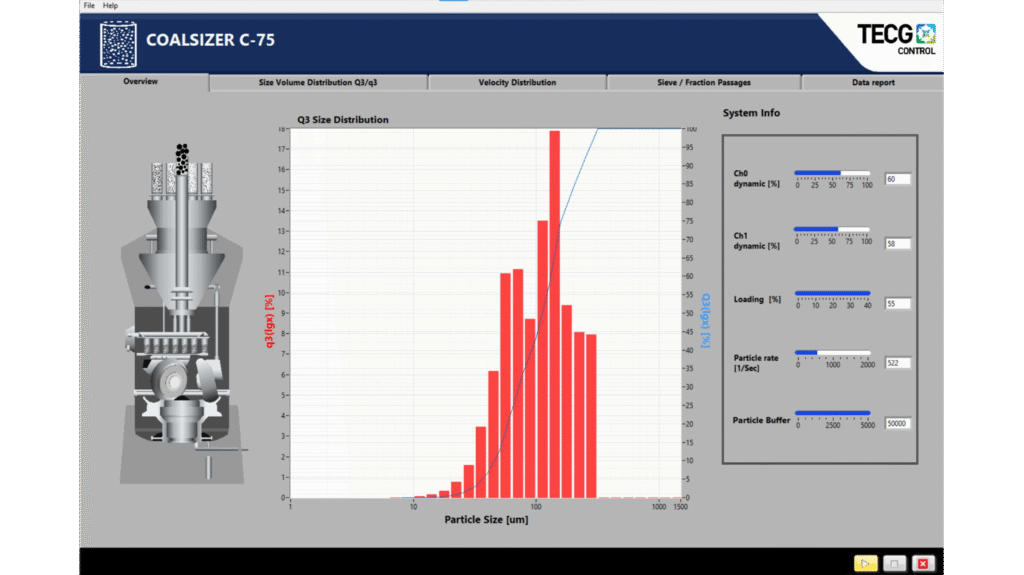

Target: Optimum coal size distribution

A common requirement is that 75% or more of coal particles pass through a 200 mesh screen (75um) in each coal pipe.

Online Measurement

Real time coal particle size distribution data is captured continuously via dedicated software, enabling instant analysis and rapid response.

Improvement Actions:

Pulverizer performance can be optimized by blueprinting tolerances and settings based on accurate particle size feedback.